$$ (b) Determine the length required for the heat exchanger.. Try the fastest way to create flashcards hello quizlet Home Subjects Expert Solutions Log in Sign up Related questions with answers

Customized Hight Performance Stainless Steel Evaporator Shell Aluminum Liquid Cold/Cooled/Cooling Plate Heat Sink with Copper Shell and Tube Heat Exchanger – China Heat Exchanger, Tube Heat Exchanger | Made-in-China.com

In summary, a counterflow, concentric tube heat exchanger is being used to cool the lubricating oil for a large industrial gas turbine engine. The flow rate of cooling water through the inner tube is 0.2 kg/s and the flow rate of oil through the outer annulus is 0.1 kg/s.

Source Image: watermanaustralia.com

Download Image

Example13.8 A tubular heat exchanger is to be designed for cooling oil from a temperature of 80°C to 30°C by a large of stagnant water which may be assumed to remain constant at a temperature of 20°C. … Example13.14 A counter-flow concentric tube heat exchanger is used to cool the lubricating oil of a large industrial gas turbine engine

Source Image: sciencedirect.com

Download Image

Hydraulic Oil Water Cooler Tubular Oil Radiator Injection Molding Machine Hydraulic System Dc-303 Tubular Heat Exchanger – Condensers & Evaporators – AliExpress [1] where Concentric tube heat exchanger design The primary advantage of a concentric configuration, as opposed to a plate or shell and tube heat exchanger, is the simplicity of their design. As such, the insides of both surfaces are easy to clean and maintain, making it ideal for fluids that cause fouling.

Source Image: savree.com

Download Image

A Concentric Tube Heat Exchanger For Cooling Lubricating Oil

[1] where Concentric tube heat exchanger design The primary advantage of a concentric configuration, as opposed to a plate or shell and tube heat exchanger, is the simplicity of their design. As such, the insides of both surfaces are easy to clean and maintain, making it ideal for fluids that cause fouling. Tempco’s T Plate range of brazed plate heat exchangers are the best solution for hydraulic oil cooling, as they are light, compact, durable and leak proof, with fast and extreme heat dissipation capacity.

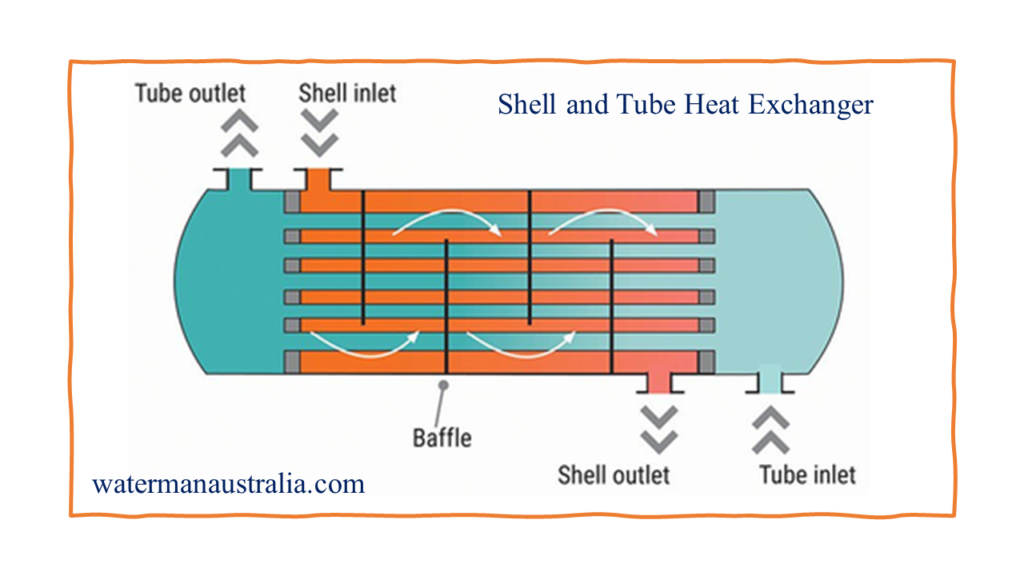

Shell and Tube Heat Exchanger Explained – saVRee – saVRee

Jul 1, 2023Volume 146, July 2023, 106896 On design and analysis of a concentric tube micro fin heat exchanger for applications of tire pyrolysis lube oil cooling Muhammad Ahmad Jamil a 1 , Haseeb Yaqoob b 1 , Binash Imteyaz c , Hafiz Muhammad Ali b c, Kashif Allahyar d , Talha S. Goraya d , Fahad Alkasmoul e , Muhammad Wakil Shahzad a Add to Mendeley Straight-Tube Heat Exchanger Shell and Tube Hex Oil Cooler – China Tube in Tube Heat Exchanger, Shell and Tube Condenser | Made-in-China.com

Source Image: jm-heat-exchanger.en.made-in-china.com

Download Image

Physical model of the ice slurry finned tube heat exchanger. | Download Scientific Diagram Jul 1, 2023Volume 146, July 2023, 106896 On design and analysis of a concentric tube micro fin heat exchanger for applications of tire pyrolysis lube oil cooling Muhammad Ahmad Jamil a 1 , Haseeb Yaqoob b 1 , Binash Imteyaz c , Hafiz Muhammad Ali b c, Kashif Allahyar d , Talha S. Goraya d , Fahad Alkasmoul e , Muhammad Wakil Shahzad a Add to Mendeley

Source Image: researchgate.net

Download Image

Customized Hight Performance Stainless Steel Evaporator Shell Aluminum Liquid Cold/Cooled/Cooling Plate Heat Sink with Copper Shell and Tube Heat Exchanger – China Heat Exchanger, Tube Heat Exchanger | Made-in-China.com $$ (b) Determine the length required for the heat exchanger.. Try the fastest way to create flashcards hello quizlet Home Subjects Expert Solutions Log in Sign up Related questions with answers

Source Image: gyheatexchanger.en.made-in-china.com

Download Image

Hydraulic Oil Water Cooler Tubular Oil Radiator Injection Molding Machine Hydraulic System Dc-303 Tubular Heat Exchanger – Condensers & Evaporators – AliExpress Example13.8 A tubular heat exchanger is to be designed for cooling oil from a temperature of 80°C to 30°C by a large of stagnant water which may be assumed to remain constant at a temperature of 20°C. … Example13.14 A counter-flow concentric tube heat exchanger is used to cool the lubricating oil of a large industrial gas turbine engine

Source Image: aliexpress.com

Download Image

Shell-Tube Type Heat Exchanger Hydraulic and Lube Oil Coolers – China Tube Sheet Heat Exchanger, in a Shell and Tube Surface Condenser | Made-in-China. com A counterflow, concentric tube heat exchanger is used to cool the lubricating oil for a large industrial gas turbine engine. The flow rate of cooling water through the inner tube (D_i = 25 mm) is 0.2 kg/s, while the flow rate of oil through the outer annulus (D_o = 45 mm) is 0.1 kg/s.The oil and water enter at temperatures of 100 and 30°C, respectively.

Source Image: tranp888.en.made-in-china.com

Download Image

Shell-Tube Type Heat Exchanger Hydraulic and Lube Oil Coolers – China Tube Sheet Heat Exchanger, in a Shell and Tube Surface Condenser | Made-in-China. com [1] where Concentric tube heat exchanger design The primary advantage of a concentric configuration, as opposed to a plate or shell and tube heat exchanger, is the simplicity of their design. As such, the insides of both surfaces are easy to clean and maintain, making it ideal for fluids that cause fouling.

Source Image: tranp888.en.made-in-china.com

Download Image

Shell-Tube Type Heat Exchanger Hydraulic and Lube Oil Coolers – China Tube Sheet Heat Exchanger, in a Shell and Tube Surface Condenser | Made-in-China. com Tempco’s T Plate range of brazed plate heat exchangers are the best solution for hydraulic oil cooling, as they are light, compact, durable and leak proof, with fast and extreme heat dissipation capacity.

Source Image: tranp888.en.made-in-china.com

Download Image

Physical model of the ice slurry finned tube heat exchanger. | Download Scientific Diagram

Shell-Tube Type Heat Exchanger Hydraulic and Lube Oil Coolers – China Tube Sheet Heat Exchanger, in a Shell and Tube Surface Condenser | Made-in-China. com In summary, a counterflow, concentric tube heat exchanger is being used to cool the lubricating oil for a large industrial gas turbine engine. The flow rate of cooling water through the inner tube is 0.2 kg/s and the flow rate of oil through the outer annulus is 0.1 kg/s.

Hydraulic Oil Water Cooler Tubular Oil Radiator Injection Molding Machine Hydraulic System Dc-303 Tubular Heat Exchanger – Condensers & Evaporators – AliExpress Shell-Tube Type Heat Exchanger Hydraulic and Lube Oil Coolers – China Tube Sheet Heat Exchanger, in a Shell and Tube Surface Condenser | Made-in-China. com A counterflow, concentric tube heat exchanger is used to cool the lubricating oil for a large industrial gas turbine engine. The flow rate of cooling water through the inner tube (D_i = 25 mm) is 0.2 kg/s, while the flow rate of oil through the outer annulus (D_o = 45 mm) is 0.1 kg/s.The oil and water enter at temperatures of 100 and 30°C, respectively.